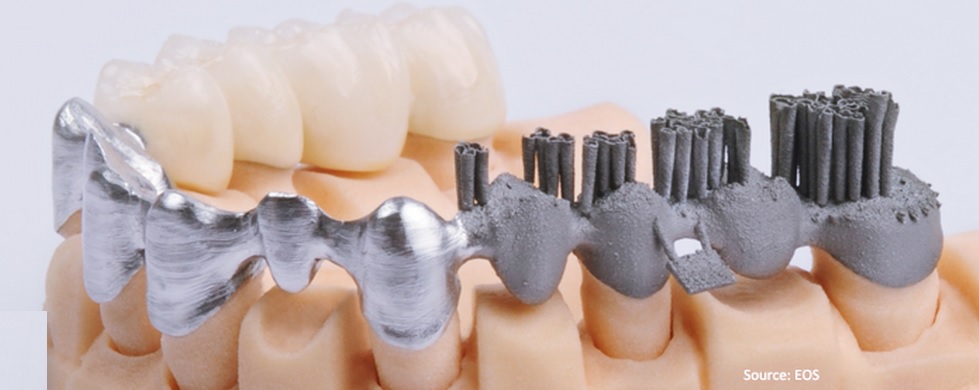

DMLS

Additive Manufacturing has been available to produce crowns and bridges since 2005. The digitally produced dental prosthesis is of a constantly high quality. Following the construction process, the dental prosthesis only has to be separated from the platform and finished. The composite strength of the ceramic veneer is outstanding compared to other manufacturing techniques. Hardly any personnel are needed to operate the EOS system. This means that two production cycles can be run per day depending on the daily number of units and capacity utilisation and up to 80,000 units can be produced each year.

Advantages

- MLS crowns and bridges are made of a particle size of 3–14 μm. This combined with very fine point laser (0.1 mm) results in a density of 99.9 %, resulting in stronger copings.

- The densely sintered crowns have practically no voids.

- The process results in highly accurate, well detailed restorations.

- Coping thickness, pontic design and cement thickness can all be standardized with this method.

- Laser sintering is a computer-controlled, precise process that ensures consistent work quality.

Additive Manufacturing is a 3D printing process that builds up parts layer. It doesn't matter whether you are producing crowns and bridges or removable partial dentures, with Additive Manufacturing solutions you always get exceptional value for money. Laboratories and manufacturing services providers can thus work much more efficiently.